Production technology of PLA film

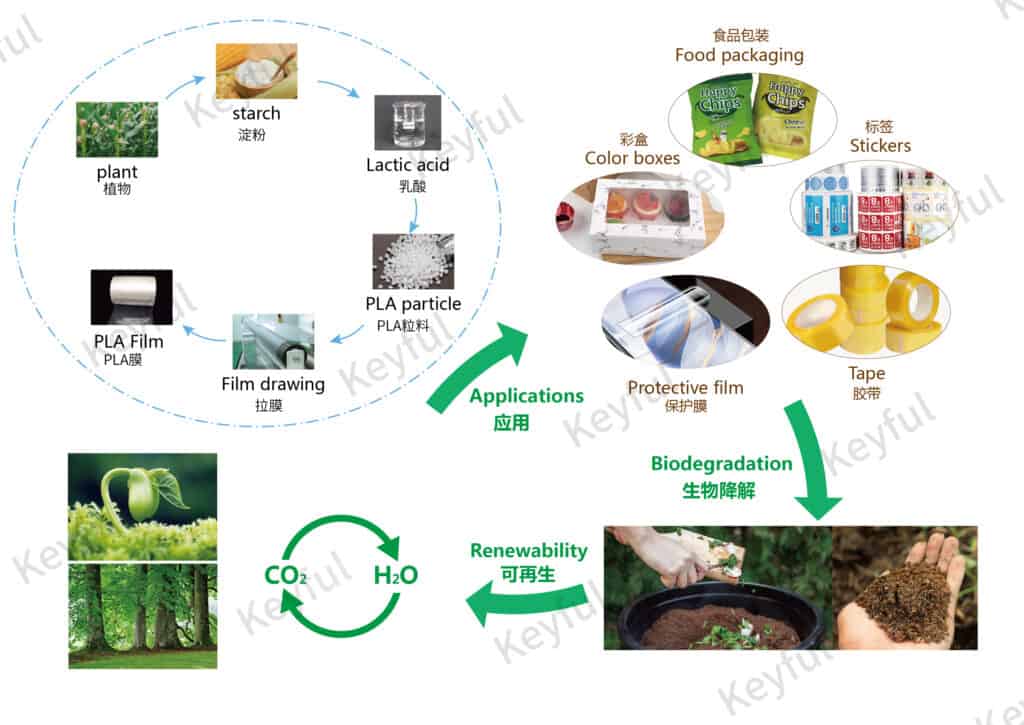

Bidirectional stretch polylactic acid film (BOPLA) can effectively meet downstream customers’ demand for high-quality biodegradable film materials, while also providing a powerful solution for China to achieve carbon peak 2030 and carbon neutral 2060 goals. It comes from plants, the raw material source is sufficient and can be recycled, the product can be biodegradable, after use can be composted, at a certain temperature or oxygen-rich and microbial action down to carbon dioxide and water, to achieve material circulation in nature, has little impact on the environment, so it is the ideal green polymer material.

Compared with other processing methods, bidirectional tensile process not only gives PLA material higher strength, but also obtains thinner film thickness, which makes the disintegration and microbial erosion process easier, and thus greatly reduces the biodegradation time of the material. Compared with traditional fossil-based polymers, PLA has reliable biosafety, biodegradability and can reduce energy dependence. Since PLA comes from biological base, it has remarkable effect on carbon reduction, with carbon emission reduced by about 70% compared with traditional fossil base material such as PP.